Sex dolls are not a new concept and these artificial lovers have been around for decades now, from basic inflatable models to lifelike companions with all the features of an actual human. Making a sex doll is a complicated procedure, numerous steps are involved in turning concept into product and eventually reaching satisfactory quality. This article will give you a great deep dive into the sex doll production process so that by the end of it, you can understand how they’re made, starting from inside of the factory to when they’re shipped.

1. Concept and Design

A sex doll begins with the concept and design phase. This stage involves a team of designers and engineers who collaborate to create a realistic and aesthetically pleasing model. The process includes:

- Market Research: Understanding consumer preferences and market trends is crucial. Companies conduct extensive research to determine the desired features, body types, and functionalities.

- Initial Sketches and Digital Models: Designers create initial sketches and digital models using computer-aided design (CAD) software. This allows for precise control over the doll’s proportions and features.

- Prototype Creation: A physical prototype is made, often using 3D printing technology. This prototype is used to assess the design and make necessary adjustments.

2. Material Selection

What is really important, though, is selecting the right materials. You want a sex doll that looks real and feels real to the touch. The most commonly used materials are:

- Silicone: Known for its lifelike texture and durability, silicone is a popular choice for high-end sex dolls.

- Thermoplastic Elastomer (TPE): TPE is a softer, more flexible material that is also used in many sex dolls. It is often chosen for its affordability and realistic feel.

- Skeleton and Joints: The internal skeleton is usually made of metal or durable plastic, providing structural support and allowing for posability.

3. Mold Creation

Once the design is finalized, molds are created for the doll’s various parts. This step involves:

- Mold Design: Engineers design molds that will shape the silicone or TPE into the desired form. These molds are often made from aluminum or steel.

- Mold Fabrication: The molds are fabricated using precision machining techniques. This ensures that every detail of the doll’s design is accurately replicated.

- Mold Preparation: Before the molding process begins, the molds are thoroughly cleaned and treated with release agents to prevent the material from sticking.

4. Casting and Molding

The casting and molding process is where the doll’s body takes shape. This involves:

- Material Preparation: The silicone or TPE is mixed and prepared for pouring. This may include adding pigments to achieve the desired skin tone.

- Pouring: The prepared material is poured into the molds, which are then sealed and heated to cure the material. The curing process can take several hours, depending on the material used.

- Demolding: Once the material has cured, the molds are opened, and the doll’s parts are carefully removed. Any excess material or flash is trimmed away.

5. Assembling the Skeleton

The internal skeleton is extremely critical in creating a sex doll. It provides structure and the ability to pose the doll in various positions. The assembly process includes:

- Skeleton Construction: The skeleton is assembled from pre-fabricated parts, including joints, hinges, and support rods. These components are usually made of metal or high-strength plastic.

- Integration with the Body: The assembled skeleton is inserted into the doll’s body parts, ensuring proper alignment and secure attachment. This step requires precision to ensure that the doll can move naturally and maintain its poses.

6. Detailing and Finishing

The sex doll is now at the beginning of the detailed finishing process after both a molded body and skeleton were combined together to provide more realism. This involves:

- Skin Texturing: The surface of the doll’s skin is textured to mimic the look and feel of real human skin. This may involve adding fine details such as pores, wrinkles, and veins.

- Painting and Blushing: Artists hand-paint the doll’s features, including the lips, nipples, and genitals. Blushing is added to give the skin a natural, lifelike appearance.

- Hair Implantation: High-quality sex dolls often feature implanted hair, which is meticulously inserted strand by strand into the scalp. This process can be time-consuming but results in a more realistic appearance.

- Makeup Application: Makeup is applied to the doll’s face, enhancing features such as the eyes, eyebrows, and lips. This step is crucial for creating a lifelike and attractive appearance.

7. Quality Control

The paramount aspect of the production cycle is quality control – overseeing that every sex doll meets high standards for realism and play. This involves:

- Inspection: Each doll is thoroughly inspected for defects, such as air bubbles, seams, or inconsistencies in the material. Any issues are addressed before the doll moves to the next stage.

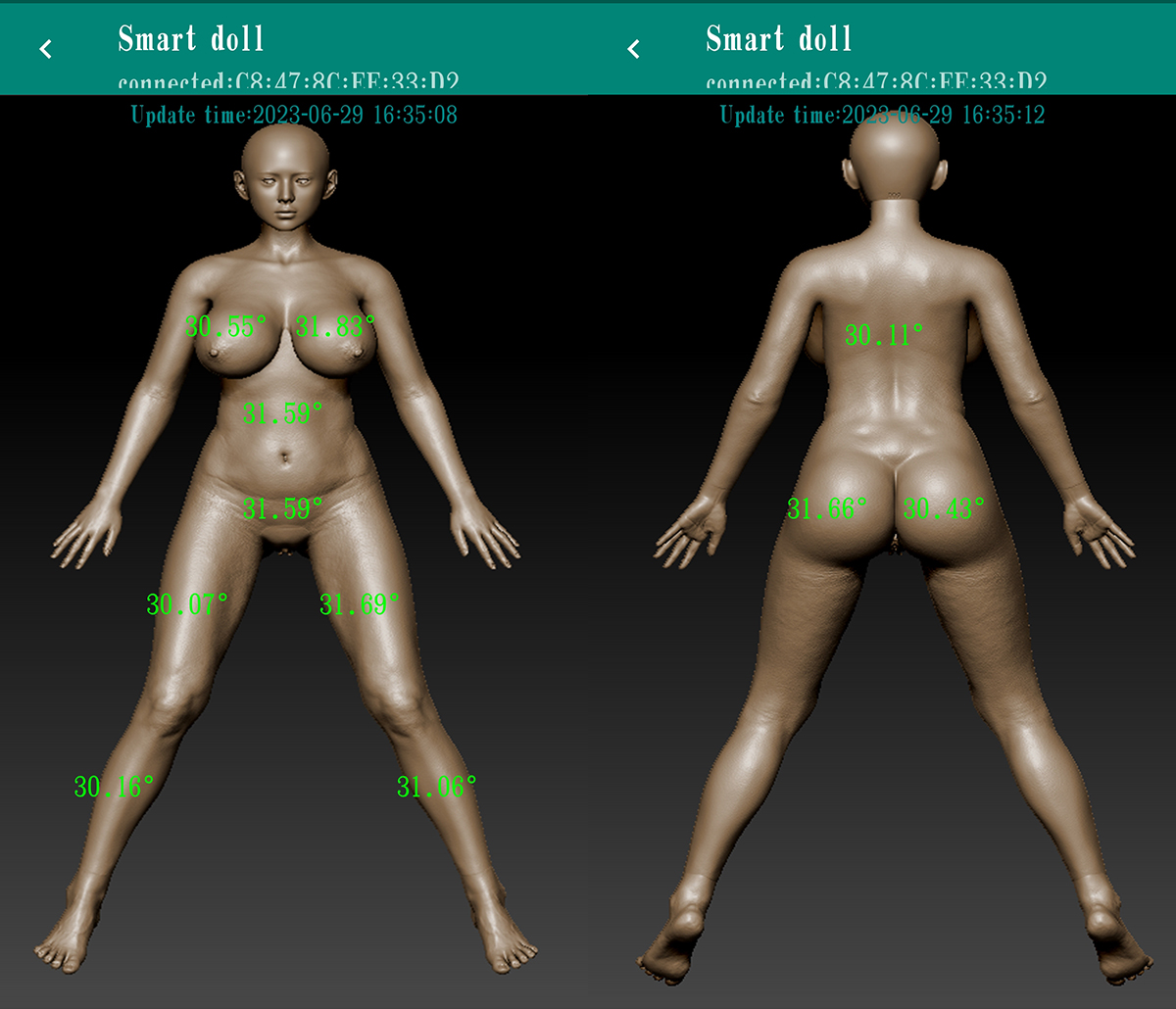

- Functionality Testing: The doll’s joints and movable parts are tested to ensure they function correctly and can hold poses. This includes checking the range of motion and stability.

- Final Touches: Any final adjustments or touch-ups are made, including additional painting, blushing, or hair styling.

8. Packaging and Shipping

Once the doll has passed quality control, it is prepared for shipping to customers. This involves:

- Cleaning: The doll is cleaned and sanitized to ensure it is ready for use upon arrival.

- Dressing: Some manufacturers dress the dolls in clothing or lingerie, depending on customer preferences.

- Packaging: The doll is carefully packaged in a sturdy box with protective padding to prevent damage during shipping. Instructions for care and maintenance are usually included.

- Shipping: The packaged doll is shipped to the customer, with tracking information provided to ensure a smooth delivery process.

9. Customer Support and Aftercare

Providing excellent customer support and aftercare is essential for maintaining customer satisfaction. This includes:

- Customer Service: A dedicated customer service team is available to answer questions and address concerns. This may include providing guidance on doll maintenance and usage.

- Repair Services: Some manufacturers offer repair services for damaged dolls, ensuring they can be restored to their original condition.

- Customization Options: Many companies offer customization options, allowing customers to personalize their dolls with specific features, such as eye color, hair style, and body type.

Conclusion

Making a sex doll is a methodical and complex procedure that unites art, engineering, as well as craftsmanship. All categories are executed with care, lifelike components, and consumer satisfaction As technology continues to advance, the realism and functionality of sex dolls are likely to improve, offering even more options and customization for those seeking companionship and pleasure.